Metal Detector for Power

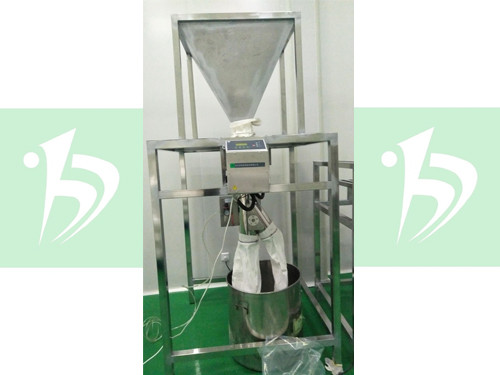

For detecting and separating metal impurities from power/granule products.(0-800kHz variable frequency)

Case Video

Work Simulation

Product Introduction

Essential Information

Quality: This machine adopts German technology. The main control board is imported from Germany so as to provide high

accuracy high sensitivity and high stability.

Application: In-line detect all kinds of materials (powder granular diamond-shaped materials etc.) for magnetic and non-magnetic

metal impurities quickly and entirely eliminate from the production line without interfering the normal production process.

And reduce material loss.

Site: This machine is suitable for high hygiene standards environment such as pharmaceutical food and chemical industries.

It can be installed in the conveyor line before processing and packaging equipment at container discharging lifting and

discharging pipe discharging or manual feeding to test the metal impurities.

Frequency: 0-800kHz high detecting frequency .

accuracy high sensitivity and high stability.

Application: In-line detect all kinds of materials (powder granular diamond-shaped materials etc.) for magnetic and non-magnetic

me

And reduce material loss.

Site: This machine is suitable for high hygiene standards environment such as pharmaceutical food and chemical industries.

It can be installed in the conveyor line before processing and packaging equipment at container discharging lifting and

discharging pipe discharging or manual feeding to test the me

Frequency: 0-800kHz high detecting frequency .

Product Advantages/ Performance Characteristics

Design: This machine is advanced design ease of installation with only four screws and well sealed.

Structure: Special structure can effectively avoid the interference of vibration noise and product effect. It is compact structure and

can be easily installed.

Appearance: Surface treatment can choose mirror polish drawing or sanding. The parts in contact with product are made of 304

stainless steel. Non-metal product channel is made of food grade materials.

Cleaning: The control case is separated from the testing unit for easy cleaning. The product channel and the rejecter can be

cleaned directly with water.

System: It has the functions of product learning and effect restraint which can be used to detect different kinds of products.

With 200 storages of different products the machine can change its product parameters in no time. It also has storage

functions of 1500 incidents (delete memory) built-in cull clock multi-program memory log in user level management

control and power failure protection.

Safety: In case of fault machine gives alarm immediately. After setting time running metal detector system gives alarm to

require a performance test by metal testing balls to confirm the functionality of the machine.

Operation: The machine can be operated in English/Chinese language through intuitive access multi-program memory.

Accuracy: The detection precision can be adjusted and 100% of the material can be detected during operation.

Rejecting: The electromagnetic valve controls the cylinder and the flap valve rejects the metal impurities automatically.

Materials: Loose dry materials (powder particles etc.) with well flow ability.

Scheme: The machine can conform to the requirements of the GMP and CE.

Levels: Protection Degrees: IP65 which can meet the requirements of HACCP certification.

Power: The whole machine power consumption is 0.035kw/H which is entirely energy saving.

Structure: Special structure can effectively avoid the interference of vibration noise and product effect. It is compact structure and

can be easily installed.

Appearance: Surface treatment can choose mirror polish drawing or sanding. The parts in contact with product are made of 304

stainless steel. Non-me

Cleaning: The control case is separated from the testing unit for easy cleaning. The product channel and the rejecter can be

cleaned directly with water.

System: It has the functions of product learning and effect restraint which can be used to detect different kinds of products.

With 200 storages of different products the machine can change its product parameters in no time. It also has storage

functions of 1500 incidents (delete memory) built-in cull clock multi-program memory log in user level management

control and power failure protection.

Safety: In case of fault machine gives alarm immediately. After setting time running me

require a performance test by me

Operation: The machine can be operated in English/Chinese language through intuitive access multi-program memory.

Accuracy: The detection precision can be adjusted and 100% of the material can be detected during operation.

Rejecting: The electromagnetic valve controls the cylinder and the flap valve rejects the me

Materials: Loose dry materials (powder particles etc.) with well flow ability.

Scheme: The machine can conform to the requirements of the GMP and CE.

Levels: Protection Degrees: IP65 which can meet the requirements of HACCP certification.

Power: The whole machine power consumption is 0.035kw/H which is entirely energy saving.

Special Description

1)Detect coil is made of stainless steel and wholly sealed inside. One time pouring and fixed.

2)Independent control system connect to sensor system by modular air plugs.

3)Independent reject unit by quick connection.

4)Open design ease of cleaning by water.

5)metal detector whole body safe structure no dead angle. Power supply is safe 24V voltage.

6)Flap rejection: quick rejection for minimum material loss do not interfere normal production process.

7)Impact structure easy for integration and installation

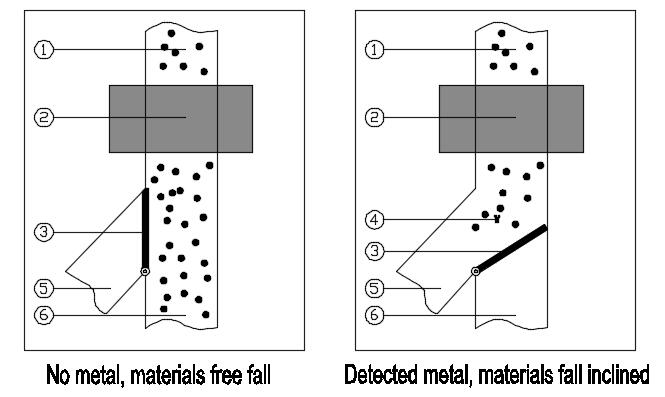

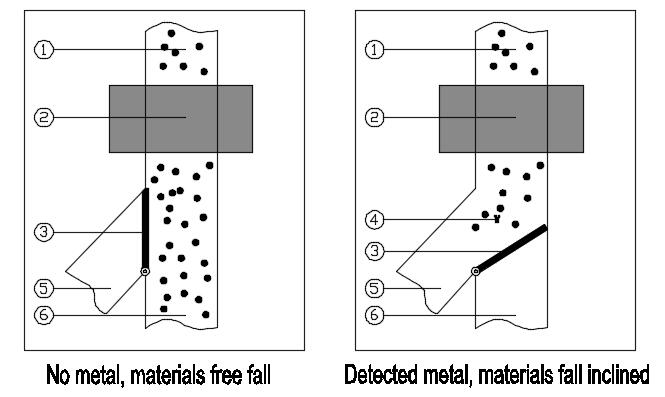

Working Principle: When metal impurities go through the metal detector head the detect coil balance was interfered. At this moment

metal detect signal is amplified and sent to detect signal. System rejects material immediately.

Working Process: Material ① falls and goes through detect coil ② metal impurities is detected and separation flap ③ is actuated

immediately. Material with metal impurities ④ is rejected from rejection tunnel ⑤.

2)Independent control system connect to sensor system by modular air plugs.

3)Independent reject unit by quick connection.

4)Open design ease of cleaning by water.

5)me

6)Flap rejection: quick rejection for minimum material loss do not interfere normal production process.

7)Impact structure easy for integration and installation

Working Principle: When me

me

Working Process: Material ① falls and goes through detect coil ② me

immediately. Material with me

Technical Parameter

| Model |

Inlet (mm) |

Sensitivity(mm) |

Dimensions (mm) |

Max Throughput(L/H) | ||

| Fe | SUS | No Fe | ||||

| P700-50 | 50 | 0.2 | 0.4 | 0.25 | 370*270*650 | 2000 |

| P700-80 | 80 | 0.35 | 0.55 | 0.42 | 430*310*705 | 8000 |

| P700-100 | 102 | 0.40 | 0.6 | 0.43 | 400*325*815 | 12000 |

| P700-120 | 116 | 0.50 | 0.7 | 0.54 | 420*325*840 | 16000 |

| P700-150 | 154 | 0.60 | 0.85 | 0.61 | 530*455*1068 | 25000 |

| P700-200 | 194 | 0.73 | 1.05 | 0.75 | 630*485*1220 | 44000 |

Remarks: maximum Stainless Steel detect precision is 0.3mm

1)Comply with national standards suitable for long time production application with stable performance.

2)Most advanced micro process control system with self learning function.

3)The system is suit for industrial environment with vibration hitting and static interference for detecting materials with water or me

4)Process parameter requirements: sensitivity is adjustable reject time is adjustable within 0.05-60 seconds gravity fall standard me

5)Main control parts are imported. Control menu is simple operation with one-button operation mode with Chinese/English operation menu.

6)Provide with me

7)Good sealing.

Quality Assurance

Accept: We accept challenge testing.

Improve: Always improve the quality of products.

Optimization: Optimize production process and improve efficiency.

Benefits: Leave the unqualified products in your workshop avoid complaints and improve your corporate image.

Purchase: Economic

Lead time: 5 days

Warranty: 12 months.

Additional warranty: Added to 5 years warranty with extra 10% cost.

After-sale: For domestic customers we promise to resolve any issues within 48 hours and change parts within warranty.

And for overseas customers we promise to send out parts within 12 hours.

Improve: Always improve the quality of products.

Optimization: Optimize production process and improve efficiency.

Benefits: Leave the unqualified products in your workshop avoid complaints and improve your corporate image.

Purchase: Economic

Lead time: 5 days

Warranty: 12 months.

Additional warranty: Added to 5 years warranty with extra 10% cost.

After-sale: For domestic customers we promise to resolve any issues within 48 hours and change parts within warranty.

And for overseas customers we promise to send out parts within 12 hours.