Pharmaceutical Metal Detector

For detecting magnetic and non-magnetic metal impurities which are enclosed in the product.(0-800kHz variable frequency)

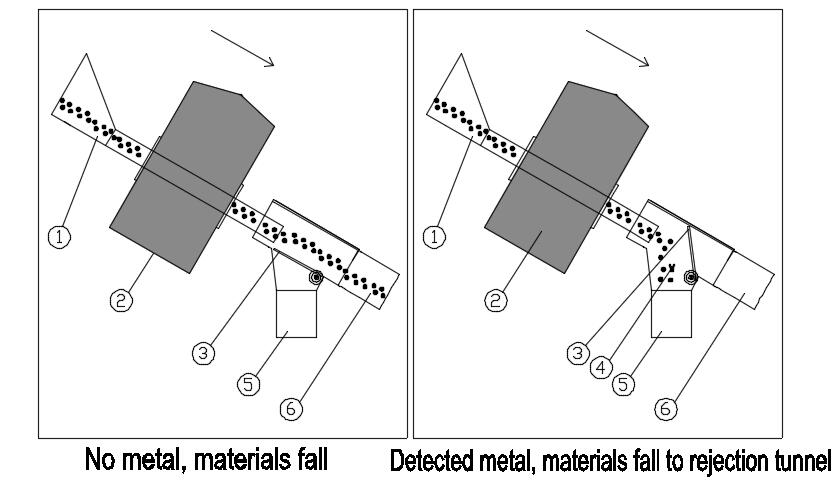

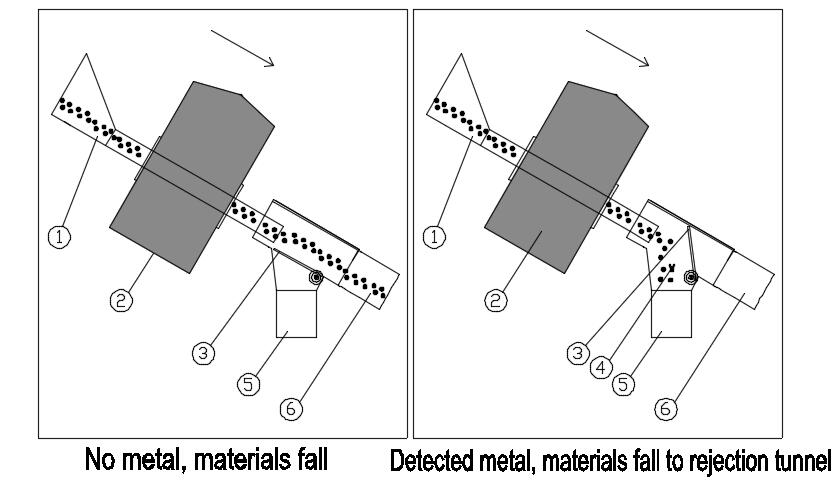

Work Simulation

Product Introduction

Essential Information

Quality: This machine adopts German technology. The main control board is imported from Germany so as to provide

high accuracy high sensitivity and high stability.

Application: Especially to use with tablet press machine and capsule filling machines to detect magnetic and non-magnetic

metal impurities and quickly reject from the production line without interfering the normal production process.

And reduce material loss.

Site: This machine can use with any model tablet press machine & capsule filling machine or use as independent unit.

Frequency: 0-800kHz high detecting frequency

high accuracy high sensitivity and high stability.

Application: Especially to use with tablet press machine and capsule filling machines to detect magnetic and non-magnetic

me

And reduce material loss.

Site: This machine can use with any model tablet press machine & capsule filling machine or use as independent unit.

Frequency: 0-800kHz high detecting frequency

Product Advantages/ Performance Characteristics

Design: Open and modular design; four units combined extremely easy for maintenance.

Height: The machine height slew angle and incline angle can be adjusted to meet requirements. The machine unit is movable.

Appearance: It is made of stainless steel 304 fully mirror polished. Product contact part is SS304 (SS316L is optional). The reject

unit and non metallic parts are all made of food grade material meet FDA requirements.

Cleaning: This machine is modular design extremely easy for cleaning.

System: It has the functions of product learning and effect restraint which can be used to detect different kinds of products.

With 200 storages of different products the machine can change its product parameters in no time. It also has storage

functions of 1500 incidents (delete memory) built-in cull clock multi-program memory log in user level management

control and power failure protection.

Safety: In case of fault machine gives alarm immediately. After setting time running metal detector system gives alarm

to require a performance test by metal testing balls to confirm the functionality of the machine.

Operation: The machine can be operated in English/Chinese language through intuitive access multi-program memory.

Accuracy: The detection precision can be adjusted and 100% of the material can be detected during operation.

Rejecting: The electromagnetic is imported flap rejects the metal impurities automatically.

Size: Opening size can be customized to suit any model of tablet press machine and capsule filling machine.

Scheme: The machine is compliment to the requirements of the GMP and CE. Meet 21 CFR part 11 certification requirements.

Levels: Protection Degrees: IP65 which can meet the requirements of HACCP certification.

Power: The whole machine power consumption is 0.035kw/H which is entirely energy saving. Power supply 220V with earthing.

Documentation: All the material certifications as well as IQ OQ PQ SOP and FAT are supplied with.

Height: The machine height slew angle and incline angle can be adjusted to meet requirements. The machine unit is movable.

Appearance: It is made of stainless steel 304 fully mirror polished. Product contact part is SS304 (SS316L is optional). The reject

unit and non me

Cleaning: This machine is modular design extremely easy for cleaning.

System: It has the functions of product learning and effect restraint which can be used to detect different kinds of products.

With 200 storages of different products the machine can change its product parameters in no time. It also has storage

functions of 1500 incidents (delete memory) built-in cull clock multi-program memory log in user level management

control and power failure protection.

Safety: In case of fault machine gives alarm immediately. After setting time running me

to require a performance test by me

Operation: The machine can be operated in English/Chinese language through intuitive access multi-program memory.

Accuracy: The detection precision can be adjusted and 100% of the material can be detected during operation.

Rejecting: The electromagnetic is imported flap rejects the me

Size: Opening size can be customized to suit any model of tablet press machine and capsule filling machine.

Scheme: The machine is compliment to the requirements of the GMP and CE. Meet 21 CFR part 11 certification requirements.

Levels: Protection Degrees: IP65 which can meet the requirements of HACCP certification.

Power: The whole machine power consumption is 0.035kw/H which is entirely energy saving. Power supply 220V with earthing.

Documentation: All the material certifications as well as IQ OQ PQ SOP and FAT are supplied with.

Special Description

1)Detect coil is made of stainless steel and wholly sealed inside. One time pouring and fixed.

2)Totally independent sensor system. Tool free dismantling easy maintenance and cleaning.

3)Independent control system connect to sensor system by modular air plugs.

4)Independent reject unit by quick connection. No need air supply.

5)Modular structure: system control box detect head reject unit machine frame are separated design easy cleaning and maintenance.

6)Open design tool free product contact parts dismantling within 10 seconds. No dead angle easy for cleaning and water wash.

7)metal detector whole body safe structure no dead angle. Power supply is safe 24V voltage.

8)Adjusting metal detector height and angle by only one operator.

Working Principle: When metal impurities go through the metal detector head the detect coil balance was interfered. At this moment metal

detect signal is amplified and sent to detect signal. System rejects material immediately.

Working Process: Material ① falls and goes through inclined detect coil ② metal impurities is detected and separation flap ③ is actuated

immediately. Material with metal impurities ④ is rejected from rejection tunnel ⑤.

2)Totally independent sensor system. Tool free dismantling easy maintenance and cleaning.

3)Independent control system connect to sensor system by modular air plugs.

4)Independent reject unit by quick connection. No need air supply.

5)Modular structure: system control box detect head reject unit machine fr

6)Open design tool free product contact parts dismantling within 10 seconds. No dead angle easy for cleaning and water wash.

7)me

8)Adjusting me

Working Principle: When me

detect signal is amplified and sent to detect signal. System rejects material immediately.

Working Process: Material ① falls and goes through inclined detect coil ② me

immediately. Material with me

Technical Parameter

| Model | Sensitivity |

Max Throughput PCS/H |

||

| Fe(mm) | SUS(mm) | NoFe(mm) | ||

| T68/18 | 0.2 | 0.4 | 0.25 | 460000 |

| T60/30 | 0.2 | 0.4 | 0.3 | 600000 |

1)Comply with national standards suitable for long time production application with stable performance.

2)Most advanced micro process control system with self learning function.

3)The system is suit for industrial environment with vibration hitting and static interference for detecting materials with water or me

element.

4)Process parameter requirements: sensitivity is adjustable reject time is adjustable within 0.05-60 seconds inclined fall standard

me

5)Main control parts are imported. Control menu is simple operation with one-button operation mode with Chinese/English operation menu.

6)Provide with me

Quality Assurance

Accept: We accept challenge testing.

Improve: Always improve the quality of products.

Optimization: Optimize production process and improve efficiency.

Benefits: Leave the unqualified products in your workshop avoid complaints and improve your corporate image.

Purchase: Economic

Lead time: 5 days

Warranty: 12 months.

Additional warranty: Added to 5 years warranty with extra 10% cost.

After-sale: For domestic customers we promise to resolve any issues within 48 hours and change parts within warranty. And for

overseas customers we promise to send out parts within 12 hours.

Improve: Always improve the quality of products.

Optimization: Optimize production process and improve efficiency.

Benefits: Leave the unqualified products in your workshop avoid complaints and improve your corporate image.

Purchase: Economic

Lead time: 5 days

Warranty: 12 months.

Additional warranty: Added to 5 years warranty with extra 10% cost.

After-sale: For domestic customers we promise to resolve any issues within 48 hours and change parts within warranty. And for

overseas customers we promise to send out parts within 12 hours.

Technical Support

For more information, please call Sales Engineer: Jinhai Yang 0532-87067772 13606300100

Download File

Please contact the sales engineer: Jinhai Yang 0532-87067772 13606300100 to get the download password. If you have obtained the download password, please click "Download File" below to download.

Download FileCustomersMore+

Pre:没有更多